What would it feel like to touch across space? To press your palm against a stranger’s palm in another part of the world. To push on their palm and feel their force as they push back.

While the speculative technology of touch across space has applications in many fields, I’d love to capture this feeling in a public sculpture. Two connected columns in separate locations that evoke play, wonder, and connectedness. Creating moments between strangers across space, and the people experiencing the magic to the left and right of you.

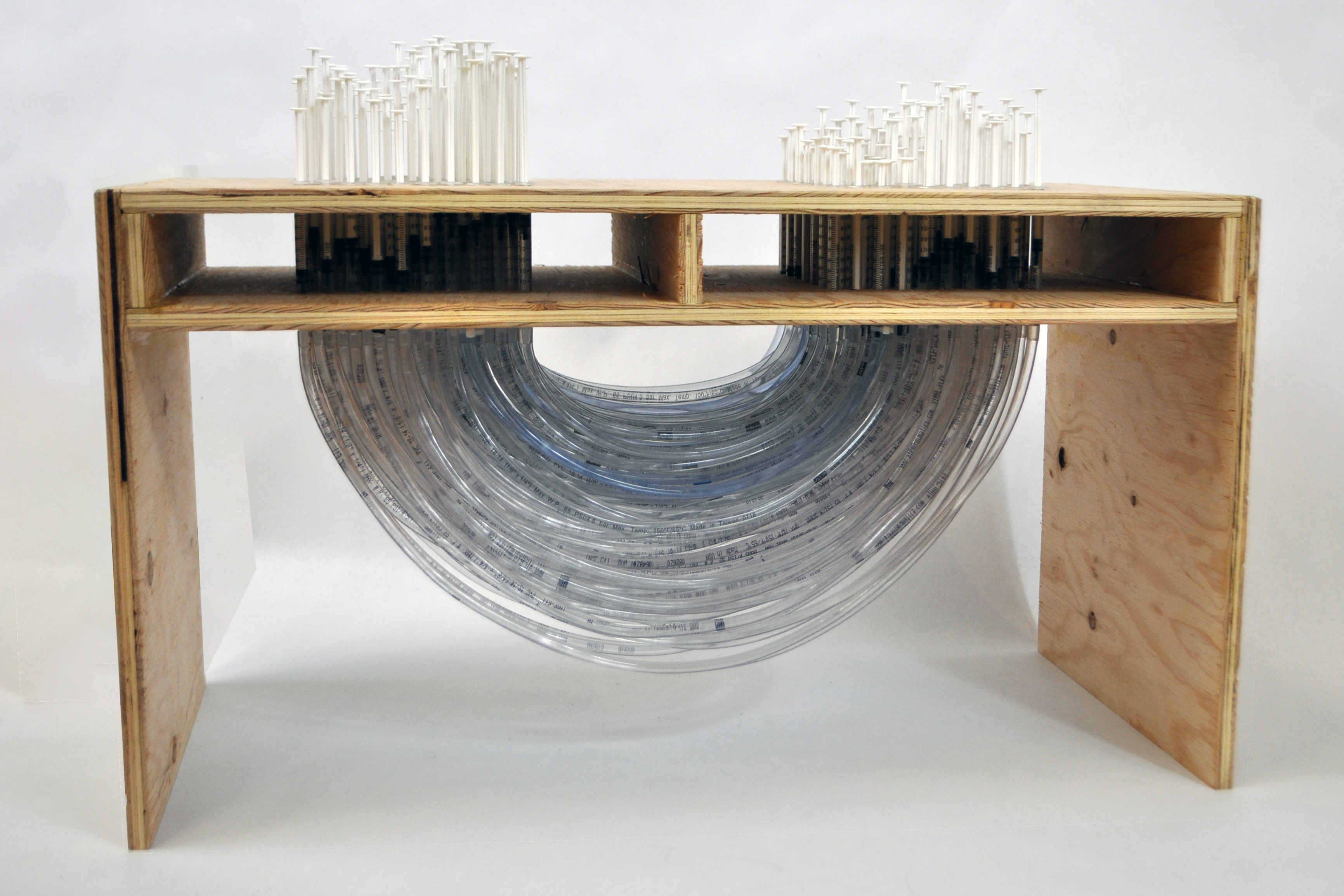

Hydraulic Study

The hydraulic feels-like model consists of a series of liquid syringes connected through vinyl tubes. The syringes are inlaid in a CNC plywood housing, creating two dense 6” x 6” polka dot grids of 260 syringes. I printed rubberized caps that press fit onto the syringe plungers. These caps created a little give, mimicking the feeling of skin. The hydraulic system is limited by the length of its hose.

User Testing

I isolated the two polka dot grids by creating a partition through the middle of the model. This eliminated sightlines between the users, helping to simulate space. Users tested the model with and without the rubber caps on the plungers. With the caps the model was described as feeling less life-like. The dampening effect of the caps decreased the feeling of individual pressure points, thus detracting from the overall experience.

The user experience was overwhelmingly positive. There were instances of participants applying simultaneous pressure (exchanging force) and turn taking (call and response). Users described the experience as being on the verge of human and inhuman, simultaneously feeling mechanical and organic. Two participants related the prototype to a typewriter. Multiple participants said they couldn’t stop smiling.

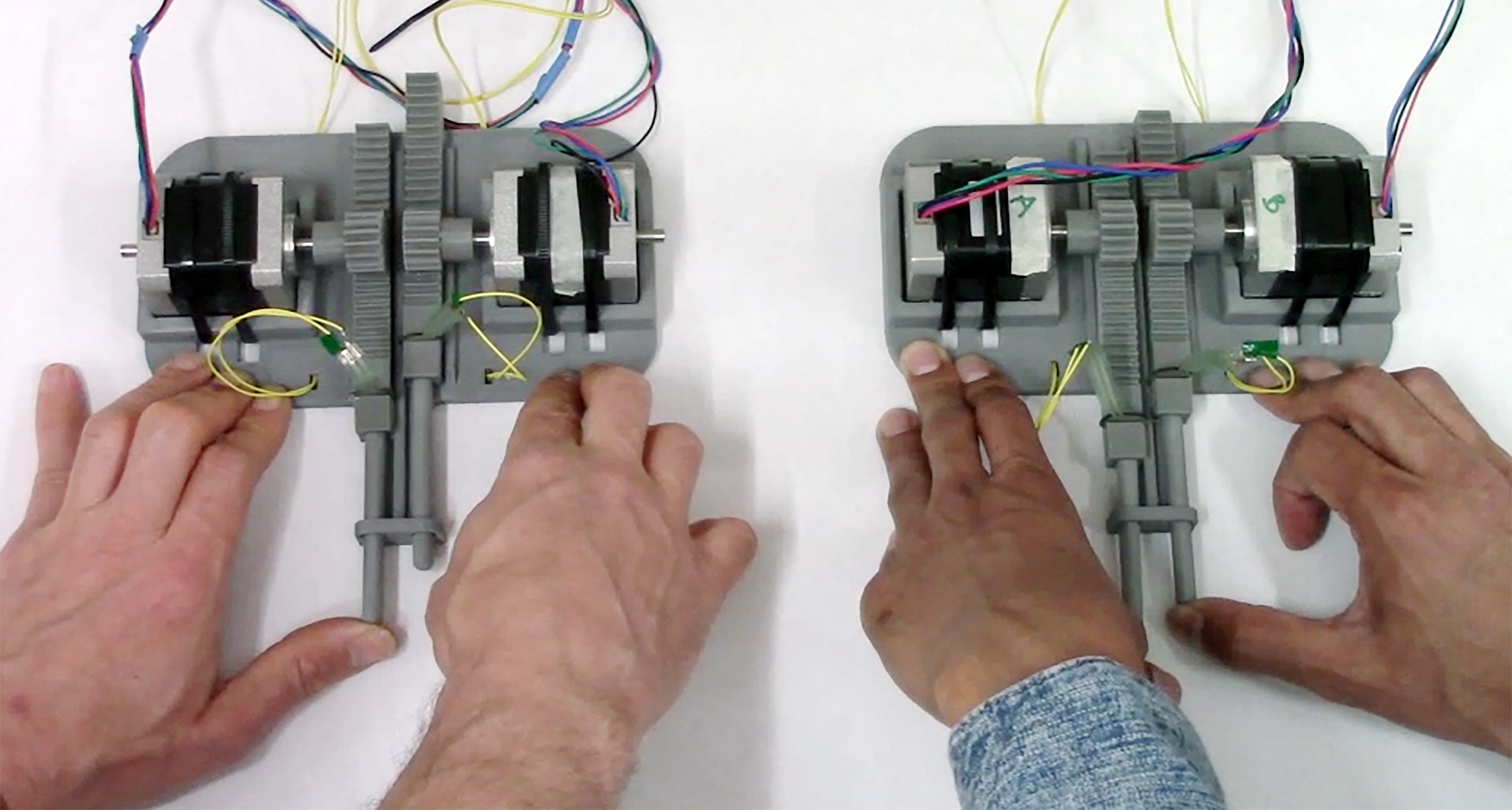

Arduino Study

I turned my attention to creating an Arduino based prototype that can work across the internet. After researching different ways to accomplish my desired effect (hydraulics, pneumatics, and linear actuators) and consulting several mechanically minded friends, I settled on a system that uses FSRs (force sensitive resistors), stepper motors, and rack and pinion gears. I utilized open source resources for this study. In turn I published my 3D models and code on Thingiverse.

Please excuse the wobbly table in GIF